PetroAcademy™ Blended Learning

Blended Learning for today's oil and gas professional

Select one or a combination of our hundreds of individual skill modules, courses, or libraries.

Individual Skill Modules

Select one or a combination of our hundreds of individual skill modules. Modules range from 2-8 hours, and allow you to complete them at your convenience.

Choose your PetroAcademy Course

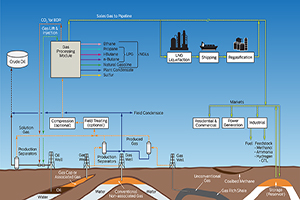

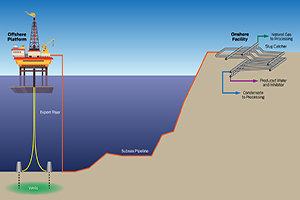

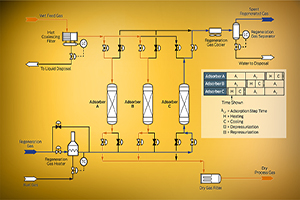

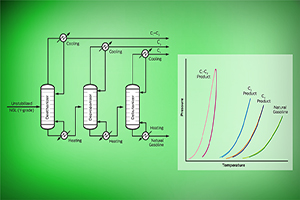

The Campbell Gas Course™ - G4 - Short Courses

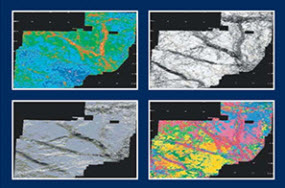

Basic Geophysics (BPG) - Short Courses

PetroAcademy Library Enterprise Subscription

Giving learners the ability to take modules on demand, whenever and wherever they need it.

An Enterprise subscription to the PetroAcademy Library of skills modules enables companies to pick and choose the modules that are most relevant to their technical professionals. Create a custom blended curriculum from our library of modules for your training needs.

Each skill module ranges from 4-10 hours, depending on the level. More advanced modules include live virtual instructor-led sessions offering learners the opportunity to review exercises and ask questions.

For Enterprise subscription pricing information, please fill out the form below and we will work with you to find a solution.