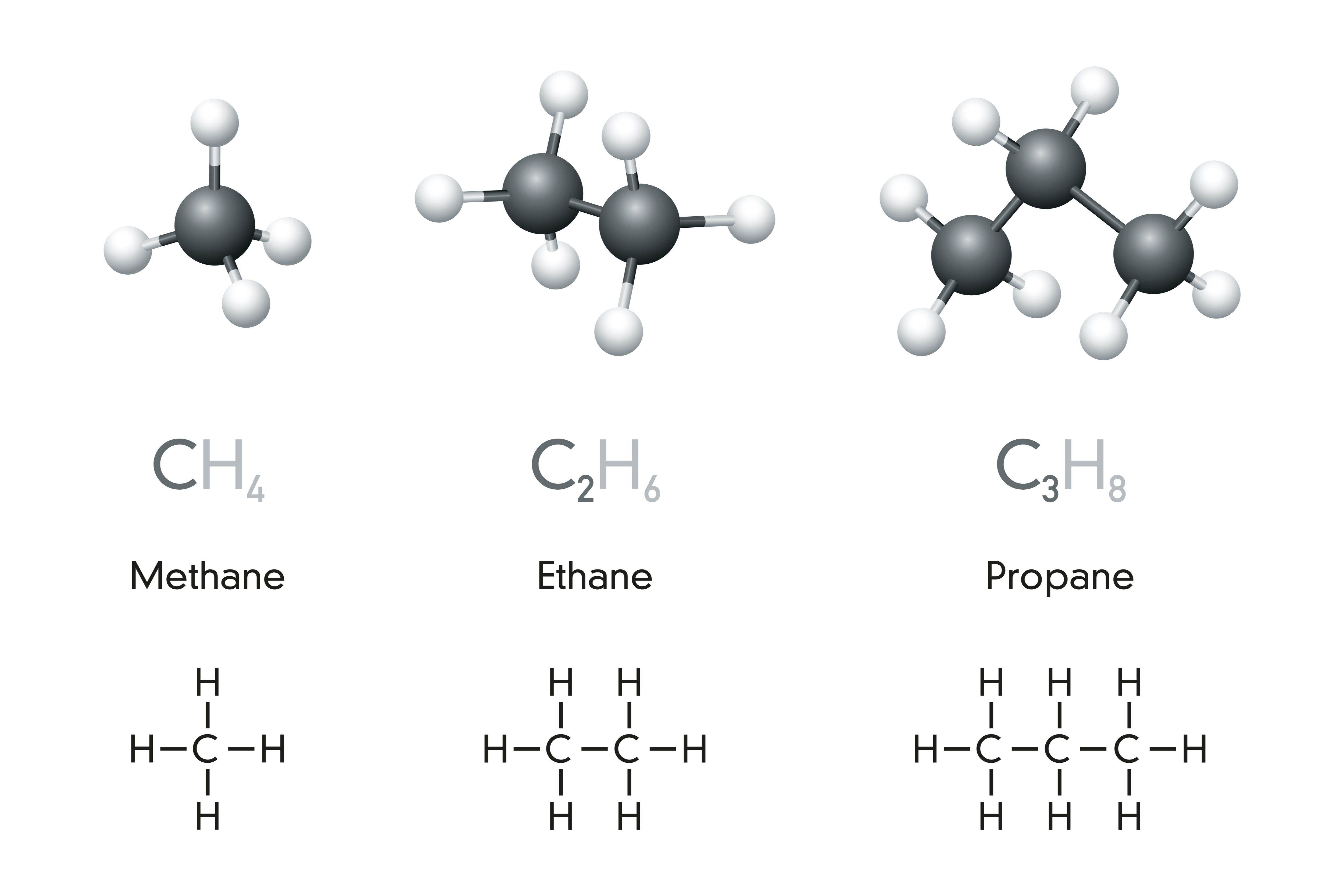

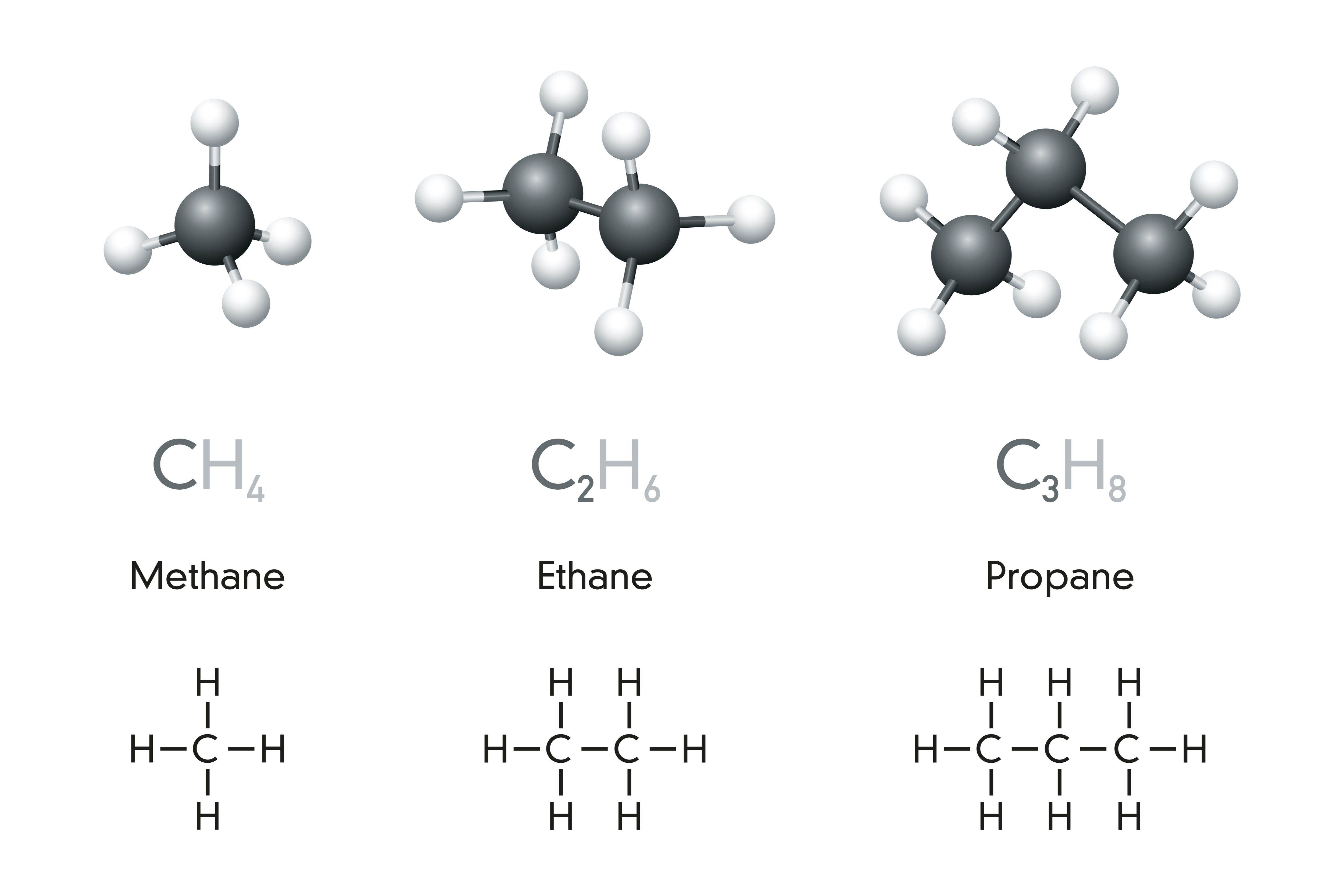

Estimation of Surface Tension of Pure Paraffin (Alkane) Hydrocarbons

December 7, 2021

|

Tip of the Month

Two simple empirical correlations and a corresponding states method reported in the literature are used to estimate pure liquids surface tensions for the paraffins methane through n-octane. The two correlations express the surface tension as a function of the reduced temperature and molecular weight with only two (first correlation) and four (secon...

View Article

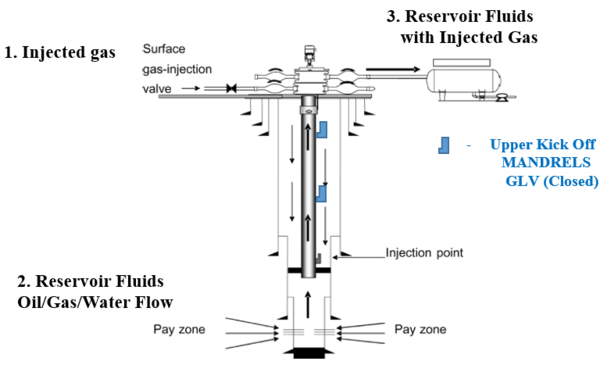

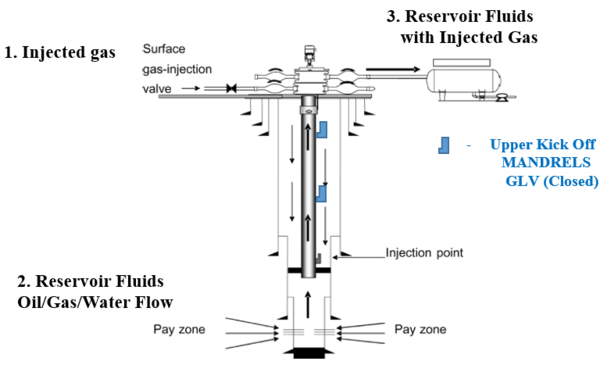

Overview of Gas Lift; Part 1: Gas Lift History, Fundamentals, Mandrels, Valve Types, and a Typical Field Installation

November 2, 2021

|

Tip of the Month

In this Part 1 presentation of the initial Gas – Lift series, and effort has been made to provide for initial orientation regarding the important Gas – Lift history, initial background, initial production efforts, Gas – Lift components, and design criteria. Oil and Gas production has been an integral part of the World’s energy based economy for ov...

View Article

Clean Energy Needs an “All of the Above” Approach to Ensure Availability and Reliability

October 4, 2021

|

Tip of the Month

This Tip of the Month will discuss energy issues in the U.S, and highlight why there must be an “all of the above” approach to electricity generation technologies to ensure availability and reliability. The type of technology selected should be based upon what the local resources and environment can provide as there is no silver bullet, or one siz...

View Article

Onshore Gas Gathering Systems – Concept Selection, Basic Design & Operation (Part 3)

September 13, 2021

|

Facilities Topics

There are several “non-metallic” options for gas gathering system applications. To a large degree, non-metallics eliminate the corrosion concerns – both internal and external – associated with metallic – typically carbon steel – pipelines.

View Article

Acid Gas Removal: Preventing Liquid Carry Over to and Condensation in the Amine Contactor

September 1, 2021

|

Facilities Topics

Hydrogen sulfide and carbon dioxide are the principal objectionable acid gas components often present in natural gas, synthetic gas, and various refinery gas streams. These acid gas components must be removed for corrosion prevention in gas pipelines, process equipment, and for health and safety reasons. Reference [1] provides current acceptable co...

View Article

Onshore Gas Gathering Systems – Concept Selection, Basic Design & Operation (Part 2)

August 30, 2021

|

Subsurface Topics

In some cases, a choke/line heater is required at the wellsite to deal with the large JT expansion cooling effect experienced by choked high-pressure wells, especially during start-up. This is a somewhat different application than prevention of hydrates in the GGS but there are some common aspects to the equipment utilized.

First, the hydrate temp...

View Article